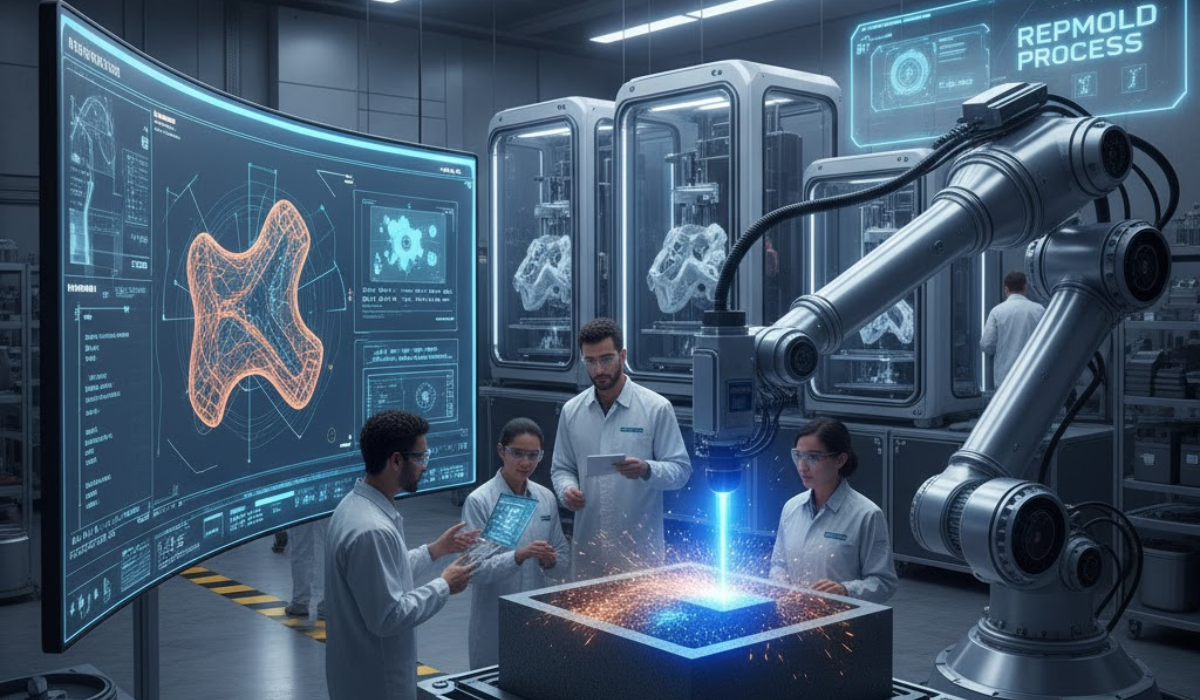

In today’s rapidly evolving industrial landscape, efficiency and precision are the cornerstones of successful manufacturing. As companies race to meet market demands while maintaining high quality and sustainability, new technologies are redefining traditional production methods. Among these innovations, Repmold stands out as a groundbreaking advancement in mold-making technology. It combines the speed of modern digital fabrication with the precision of traditional craftsmanship—reshaping how molds are designed, tested, and produced.

What Is Repmold?

Repmold refers to an advanced mold-making process that leverages a combination of digital design, additive manufacturing, and high-precision machining to create molds faster and more accurately than ever before. Unlike conventional methods that rely heavily on manual labor and long lead times, Repmold utilizes computer-aided design (CAD), 3D printing, and computer numerical control (CNC) machining to streamline the entire workflow.

The central philosophy of Repmold is efficiency without compromise. Manufacturers can produce molds that meet the most demanding specifications while reducing production time, minimizing material waste, and improving overall product consistency.

Historical Context: From Handcraft to High-Tech Precision

Mold-making has ancient origins. Early artisans sculpted molds by hand from clay, stone, or wood to shape materials like metal and ceramics. This manual process demanded tremendous skill, and even small mistakes could lead to costly errors.

The Industrial Revolution marked a major shift. Mechanization introduced metal molds and machine-based manufacturing, increasing productivity and standardizing results. Over the centuries, techniques continued to evolve, incorporating new materials such as silicone, aluminum, and steel.

Repmold represents the latest evolution in this journey—a fusion of digital intelligence and engineering precision. By integrating automation and advanced materials, it transcends the limits of traditional craftsmanship, achieving results that were once unimaginable.

Core Technologies Behind Repmold

Repmold technology brings together several cutting-edge tools and methods that work in harmony to deliver unmatched efficiency and precision.

1. Computer-Aided Design (CAD)

At the heart of Repmold lies CAD software. Engineers use it to design detailed 3D models of molds with exact specifications. These digital blueprints ensure every curve, groove, and dimension aligns with the desired output. CAD also allows for easy adjustments, enabling rapid design modifications before physical production begins.

2. Additive Manufacturing (3D Printing)

3D printing plays a critical role in the Repmold process. It allows manufacturers to rapidly prototype molds or components, testing designs in real-time without significant material costs. By layering materials with high accuracy, 3D printing accelerates innovation cycles and supports experimentation with complex geometries.

3. CNC Machining

Once the design is finalized, CNC machines execute precision cutting, drilling, and shaping tasks. These automated tools ensure consistency and eliminate the variability associated with manual machining. CNC technology provides the accuracy necessary for high-performance molds used in demanding industries like aerospace and automotive manufacturing.

4. Digital Simulation

Before molds go into production, digital simulations can test how materials will behave under heat, pressure, and stress. This predictive capability minimizes costly trial-and-error testing and ensures that the final molds meet performance standards before physical creation begins.

Applications of Repmold Technology Across Industries

Repmold is not limited to a single sector—it has broad applications across various fields due to its adaptability and speed.

Automotive Industry

In automotive manufacturing, Repmold helps produce components with strict safety and dimensional standards. Complex parts such as engine housings, dashboards, and aerodynamic elements can be created quickly and precisely, allowing manufacturers to stay competitive in a fast-paced market.

Consumer Electronics

From smartphone casings to microcircuit boards, consumer electronics require molds that meet high aesthetic and functional standards. Repmold ensures that each design maintains perfect symmetry and finish, enhancing both product reliability and visual appeal.

Medical Equipment

Precision is vital in the medical industry, where molds are used for surgical tools, prosthetics, and diagnostic devices. Repmold’s ability to deliver accurate and sterile mold designs ensures compliance with strict medical standards.

Aerospace Engineering

Aerospace components must endure extreme conditions while maintaining lightweight properties. Repmold facilitates the creation of complex, aerodynamic molds used for turbine blades, composite panels, and structural parts.

Cultural and Artistic Manufacturing

Beyond industrial applications, Repmold is increasingly used in art, jewelry, and restoration work. Its precision allows artisans to reproduce intricate details while maintaining the essence of traditional craftsmanship.

Advantages of Repmold

1. Speed and Efficiency

Repmold drastically reduces lead times by integrating digital workflows. What once took weeks can now be completed in days, giving manufacturers a competitive advantage in responding to market trends.

2. High Precision and Consistency

With digital control and automated machinery, Repmold achieves exceptional accuracy. This reduces production defects, ensuring that every product maintains consistent quality.

3. Cost-Effectiveness Over Time

Although the initial investment in Repmold technology may be high, the reduction in waste, faster turnaround times, and lower labor costs provide long-term savings.

4. Environmental Sustainability

By optimizing material usage and enabling rapid design testing, Repmold minimizes waste generation. Manufacturers can test multiple iterations digitally before committing to full-scale production, aligning with modern sustainability goals.

5. Flexibility in Production

Repmold can handle both small-scale prototyping and large-scale manufacturing efficiently. This adaptability makes it suitable for startups, research labs, and established industries alike.

Challenges and Limitations

Despite its numerous advantages, Repmold is not without challenges.

- High Initial Costs: Implementing advanced equipment, software, and training can require substantial investment.

- Material Compatibility: Not all materials respond equally well to the rapid prototyping methods used in Repmold. Some may require additional testing or hybrid processes.

- Skilled Workforce Requirements: Operating digital design tools and precision machinery demands expertise. Manufacturers must invest in skilled engineers and continuous training.

However, as the technology matures and becomes more accessible, these challenges are steadily diminishing.

The Cultural and Industrial Impact of Repmold

Repmold not only revolutionizes manufacturing but also bridges the gap between art and engineering. It brings back the human touch of creativity while leveraging digital precision. Artists, designers, and engineers can now collaborate more easily, creating products that balance aesthetic appeal and functional efficiency.

On an industrial scale, Repmold embodies the future of Industry 4.0, where automation, data, and connectivity drive smarter manufacturing. The technology aligns perfectly with global trends emphasizing sustainability, customization, and digital transformation.

The Future of Repmold Technology

As technology continues to advance, the future of Repmold looks incredibly promising. Several key trends are shaping its evolution:

- AI Integration: Artificial intelligence can optimize mold designs by predicting performance outcomes and automatically suggesting improvements.

- Advanced Materials: New composites and temperature-resistant materials are expanding the range of applications for Repmold.

- Automation and Robotics: Fully automated systems will further reduce manual intervention, ensuring round-the-clock production with minimal errors.

- Global Accessibility: As costs decline, small and medium-sized manufacturers will gain access to Repmold technology, democratizing innovation across industries.

Repmold represents not just a new technique—but a paradigm shift in how products are conceived, designed, and manufactured.

Informational FAQs

1. What makes Repmold different from traditional mold-making methods?

Repmold combines digital design, 3D printing, and precision machining to create molds faster and with greater accuracy than traditional techniques.

2. Is Repmold suitable for small-scale production?

Yes, Repmold’s adaptability makes it ideal for both small prototype runs and large-scale industrial manufacturing.

3. Does Repmold support sustainable manufacturing?

Absolutely. It reduces material waste through digital simulation and rapid prototyping, making it an eco-friendly alternative to conventional mold-making.

4. What industries benefit most from Repmold?

Automotive, aerospace, medical devices, consumer electronics, and cultural manufacturing are among the key industries that benefit from Repmold’s precision and speed.

5. What are the limitations of Repmold technology?

The main challenges include high initial setup costs, limited material compatibility, and the need for skilled technical operators.