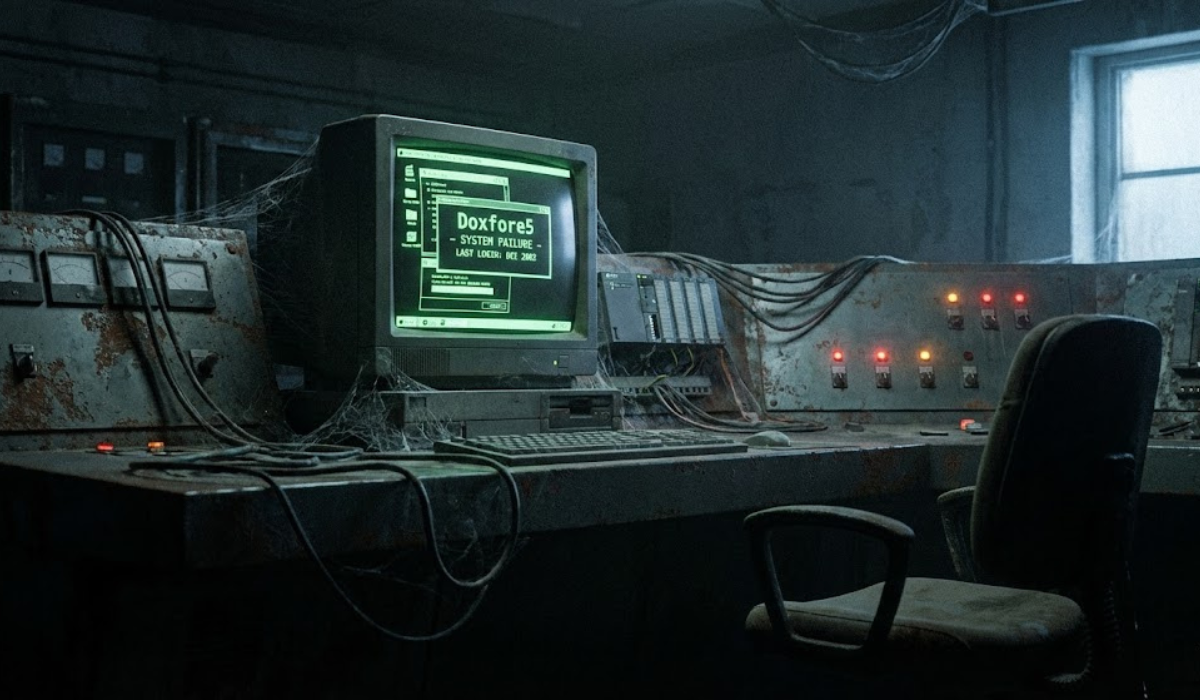

In the fast-moving world of digital technology, nothing lasts forever—not even the tools that once felt essential to daily operations. The search term “sofware doxfore5 dying” might look like a typo-ridden phrase from a frustrated user, but it reflects a real concern happening behind the scenes. Many individuals and organizations still rely on older utilities like Doxfore5, and now they face a tough truth:

Doxfore5 is obsolete, unsupported, and officially in its end-of-life (EOL) stage.

For decades, Doxfore5 served niche technical roles—especially within industrial automation systems connected to SattControl platforms. It was never mainstream, but for those who depended on it, it was reliable. Now, as the digital ecosystem evolves, this once-trusted software is reaching the end of its natural lifecycle.

Before we dive into the risks and recommendations, let’s clarify what the “death” of software actually means—and why Doxfore5 is a textbook example of it.

What Does It Mean When Software Is “Dying”?

Software rarely disappears overnight. Instead, its decline follows a recognizable pattern:

1. Development Slows Down

Updates become infrequent. Bug fixes stop. New features vanish.

2. Official Support Ends

Developers move on, companies shut down websites related to the tool, and no one is left to maintain or troubleshoot the product.

3. Security Vulnerabilities Grow

Old code becomes easy prey for modern cyberthreats.

4. Compatibility Fades

New operating systems, modern hardware, and updated industrial platforms no longer communicate with the old software.

5. Users Begin Searching for Answers

That’s where phrases like “sofware doxfore5 dying” come from. People sense the decline and start looking for clarity.

This lifecycle is exactly what’s happening with Doxfore5 today.

The Current Status of Doxfore5: A Clear End-of-Life Scenario

Based on industry information, legacy documentation, and statements from automation specialists, the situation for Doxfore5 is unambiguous:

It is fully obsolete and officially in an end-of-life phase.

Here’s what that means in practical terms:

1. No Support or Updates from Original Developers

The team originally behind Doxfore5 associated historically with SattControl has abandoned the platform.

- No patches

- No security updates

- No customer service

- No website maintenance

- No migration tools

This is the clearest indicator that “Doxfore5 is dying” is more than a rumor—it’s a verifiable fact.

2. Serious Security Vulnerabilities

Using unsupported software is like leaving your front door unlocked in a dangerous neighborhood.

Without updates, vulnerabilities pile up. Cybercriminals know this. Any system running Doxfore5 today may be exposed to:

- Malware infections

- Ransomware attacks

- Unauthorized access

- Data leaks

- Manipulation of industrial operations

In industrial automation, where Doxfore5 was used to manage certain PLC configurations, the risks multiply. A compromised control system can interrupt operations, damage equipment, or halt production entirely.

3. Hardware and System Compatibility Failures

Modern ecosystems have moved far beyond the era when Doxfore5 was created.

Users now report issues such as:

- Inability to install or run on new operating systems

- Broken communication with new or upgraded PLCs

- Data corruption

- Missing drivers

- Frequent crashes and instability

This is typical of end-of-life software that was never designed to coexist with today’s tools.

4. Difficulty Accessing or Preserving Old Files

Another reason users search for “sofware doxfore5 dying” is fear of losing access to legacy documents or automation routines.

Old systems produce:

- Configuration files

- Automation scripts

- Operational instructions

- Documentation data

Once the software dies, accessing or converting these becomes increasingly difficult unless steps are taken immediately.

Why People Still Use Doxfore5 Today

Even when software is outdated, certain groups remain loyal—sometimes by choice, but often out of necessity.

1. Legacy hardware depends on it

Specific PLC systems and industrial automation platforms still rely on Doxfore5-formatted configurations.

2. Migration feels expensive or confusing

Replacing hardware and rewriting programs requires expertise, time, and budget.

3. “If it works, don’t change it.”

Many industrial environments value stability above everything else. If a setup has worked for years, changing it feels risky.

But sticking with an obsolete tool has growing consequences—especially now.

Risks of Continuing to Use Doxfore5

Let’s break down the real-world dangers:

1. System Failure Without Warning

Old tools fail unpredictably. There’s no support to recover lost data or fix corrupted configurations.

2. Downtime in Industrial Operations

If Doxfore5 is controlling a production line or PLC, failures can halt operations entirely.

3. Data Loss

Unsupported file formats can become unreadable on new systems.

4. Threat Exposure

Security gaps invite serious cyber threats.

5. Lost Productivity

Teams waste time troubleshooting a system no longer meant to function in modern environments.

Recommended Actions: What Users Should Do Now

If you or your organization still rely on Doxfore5, immediate planning is crucial.

1. Replace the SattControl PLC System

Modern, supported PLC hardware is the best long-term solution.

This involves:

- Selecting a modern PLC system

- Rewriting existing programs

- Using available documentation or printouts to recreate logic

- Verifying the new system meets current operational needs

This approach future-proofs your system and eliminates the risks of old, unsupported software.

2. Explore Modern Software Alternatives

There are newer tools offering:

- Active support

- Regular security updates

- Compatibility with current industrial standards

- Easier configuration and integration

- Advanced features such as cloud syncing, real-time monitoring, and data analytics

Switching to a newer platform means fewer headaches and greater stability moving forward.

3. Consult Industrial Automation Specialists

Experts can help with:

- Migrating old configurations

- Converting legacy routines into modern formats

- Installing new hardware

- Testing systems for safety and efficiency

- Training your team on updated tools

A structured migration reduces the risk of operational downtime.

Is Doxfore5 Truly “Dying”—or Already Gone?

In practical terms, Doxfore5 is no longer dying—it’s already dead.

The only people keeping it alive are users who haven’t yet migrated away. And while nostalgia and familiarity are powerful motivators, they can’t protect against:

- cyberattacks

- production failures

- data loss

- compatibility collapses

In the long run, it’s far safer and more efficient to move on.

FAQs (Informational)

1. Why is “sofware doxfore5 dying” a trending search?

Because users are noticing growing issues—crashes, incompatibility, and lack of support—and they want answers about the software’s status.

2. Is Doxfore5 still supported today?

No. All development and support were discontinued years ago.

3. Is it safe to continue using Doxfore5?

No. The software poses significant security risks, especially in sensitive industrial environments.

4. What happens to my old Doxfore5 files?

They may become unreadable on modern systems unless migrated or converted with specialist tools.

5. What is the recommended alternative to Doxfore5?

Switch to modern industrial automation software and update your PLC hardware to supported systems.

6. Can specialists help migrate from Doxfore5?

Yes. Automation experts can help convert old programs, preserve system logic, and install modern replacements.

7. What is the consequence of delaying migration?

Greater risk of system failure, cybersecurity threats, and potentially expensive downtime.